27 octobre 2024

- Production of drinking water by low-pressure reverse osmosis / Hugo Taligrot PhD Defense

Doctorant : Hugo Taligrot

Date : Wednesday November 27, 2024 at 9am in the Cerege Amphitheatre at the Technopôle de l'Arbois-Méditerranée

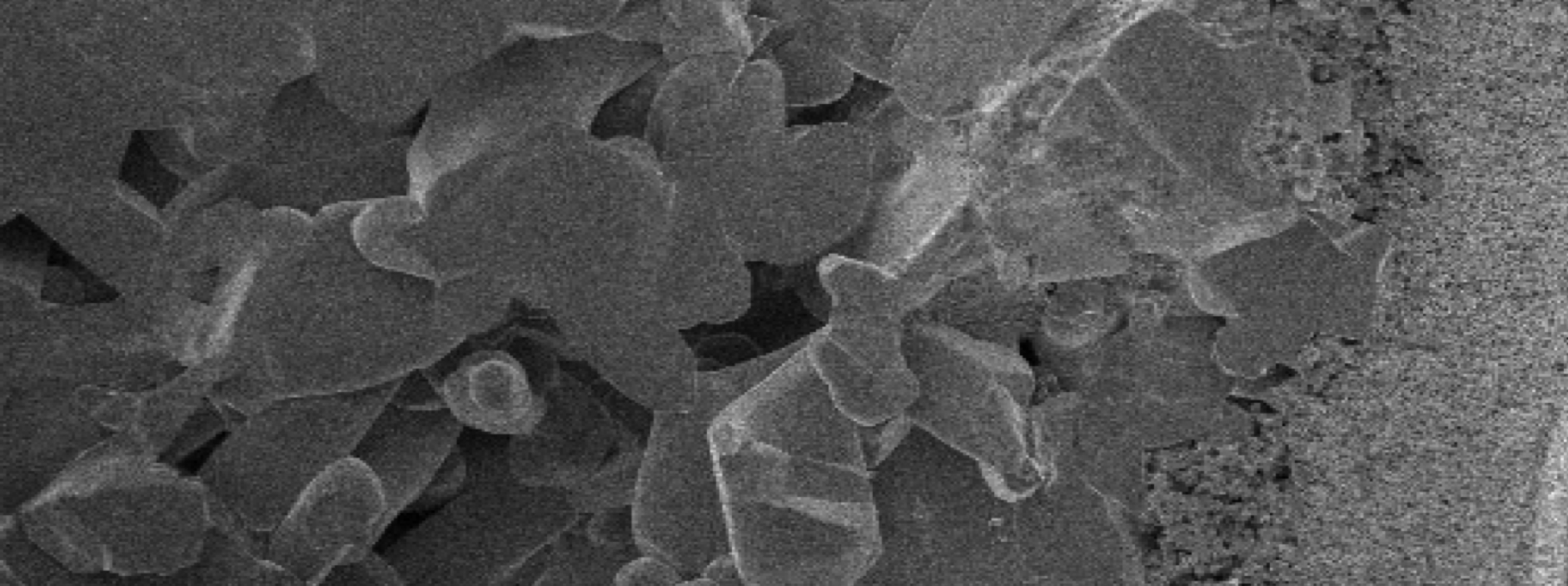

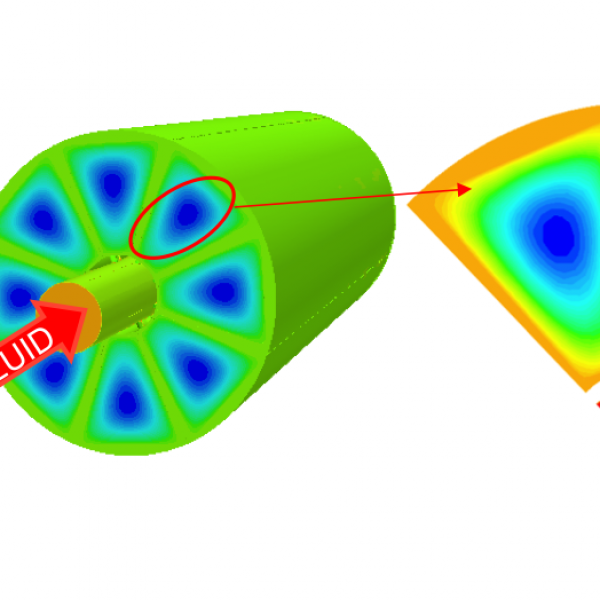

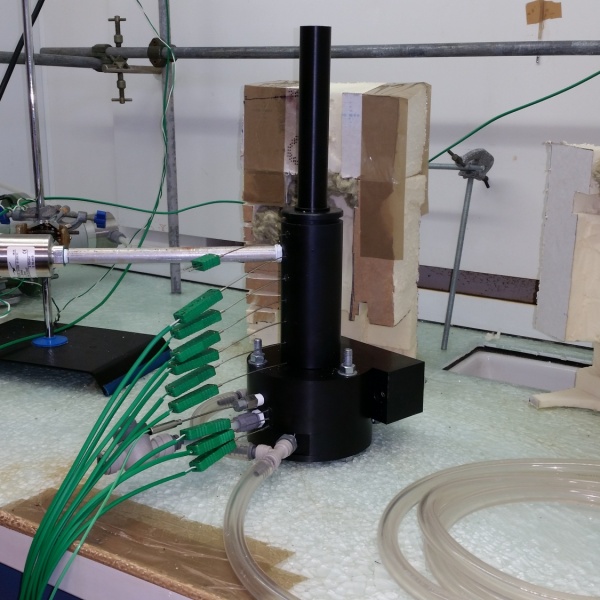

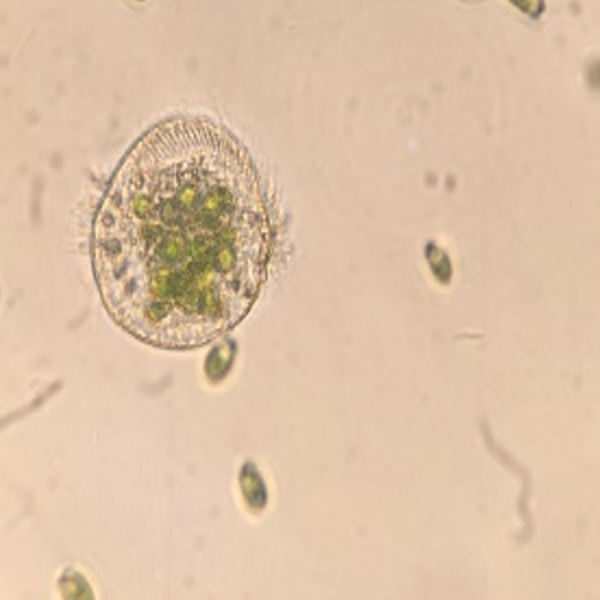

Abstract: Freshwater is essential for life, ecosystems and industry, but the intensification of human, agricultural and industrial activities is leading to high demand coupled with a decline in the quality of natural water. In the context of producing drinking water from natural freshwater, some pollutants are not completely stopped by conventional processes and can threaten public health, such as viruses and microplastics. Membrane processes are renowned for their ability to reduce effluent volumes while producing a very high quality permeate. The limitations of ultrafiltration, used for freshwater purification, in the face of the emergence, omnipresence or persistence of contaminants have led to attention being focused on low-pressure reverse osmosis (LPRO), recognised for its higher retention potential. This thesis aims to demonstrate (i) the potential of LPRO to produce high-quality drinking water from fresh water, while addressing the challenges associated with the retention of viruses and then microplastics, as well as (ii) the durability of the membranes. Finally, the stability of water quality in distribution networks will be studied in order to cover the supply chain. Although the literature indicates high viral abatement for LPRO, these results do not always reflect reality, as they are based on individual model viruses at concentrations much higher than those found in natural freshwater, in order to promote their detection in the permeate. In this study, concentration methods were developed to analyse large volumes of permeate at low virus concentrations, enabling the limit of quantification to be reduced and the performance of the LPRO process to be assessed. The LPRO process was studied on two scales (laboratory and semi-industrial) with regard to the retention of two pathogenic enteric viruses and a model virus, respectively an adenovirus (AdV 41), an enterovirus (CV-B5) and the bacteriophage MS2, at concentrations representative of those found in the environment. The concentration methods proved effective in treating the permeates from each LPRO pilot scale. The LPRO process achieves significant virus removal (6 log on average) at different scales, although total retention is not achieved. In-depth analysis of used LPRO spiral wound modules has suggested that viral retention defects may originate from the module’s O-rings and possibly its glue lines, but not from the membrane if it is intact. In fact, various defects were observed during the autopsy of the LPRO modules (folded or abraded membrane, presence of patches), which had a significant impact on performance. Analysis of the ageing of the spiral-wound modules revealed a reduction in membrane performance in terms of permeability and retention rate for monovalent (NaCl) and divalent (CaSO4) salts. However, the retention rate for microplastics (tested on polymethyl methacrylate beads) remained total, with reductions of over 7 log. Finally, water produced by LPRO and injected into a simulated distribution network showed reduced bacterial growth potential, with a lower concentration of active cells measured by flow cytometry and lower total organic carbon, compared with water produced by a conventional process or by ultrafiltration.

Keywords: low-pressure reverse osmosis, drinking water production, enteric viruses, microplastics, membrane ageing, biological stability

Jury:

Clémence COETSIER, Reviewer, AP, Paul Sabatier University

Jean Philippe CROUE, Reviewer, PR, University of Poitiers

Isabelle BERTRAND, Examiner, AP, University of Lorraine

Jean-Luc BOUDENNE, President of the jury, PR, Aix-Marseille University

Philippe MOULIN, Thesis Supervisor, PR, Aix-Marseille University

Mathias MONNOT, Thesis Supervisor, AP, Aix-Marseille University

Laurent MOULIN, Guest Member, Head of R&D, Eau de Paris

Sébastien WURTZER, Guest Member, Molecular and Emerging Pathogens Manager, Eau de Paris