22 janvier 2026

- Study of Combustion Instabilities Using Lattice-Boltzmann Methods / PhD Defense Ziyin Chen

Doctorante : Ziyin CHEN

Date et lieu : le jeudi 22 janvier 2026 à 13h45; amphi No.1 de Centrale Méditerranée

Abstract: Driven by climate change and the energy transition, hydrogen has emerged as a promising alternative to fossil fuels due to its efficient, carbon-free combustion. However, hydrogen–air flames exhibit strong instabilities, which are amplified in confined environments where wall effects and heat losses play a key role. Understanding these phenomena is essential for the safe design of micro-scale combustion devices.

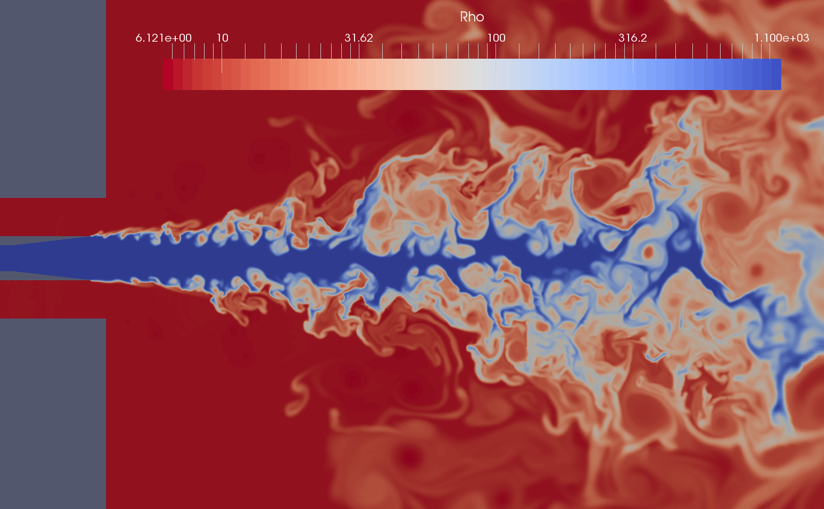

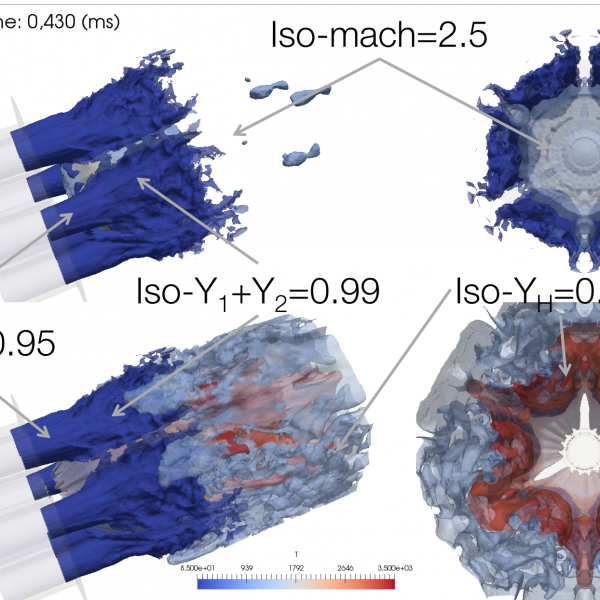

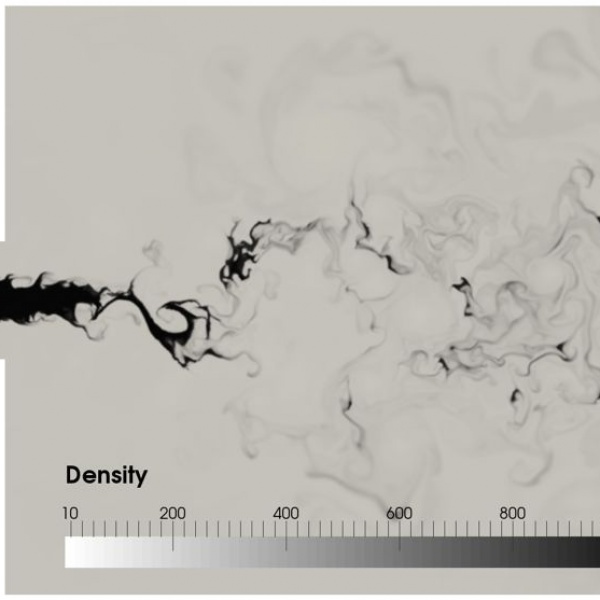

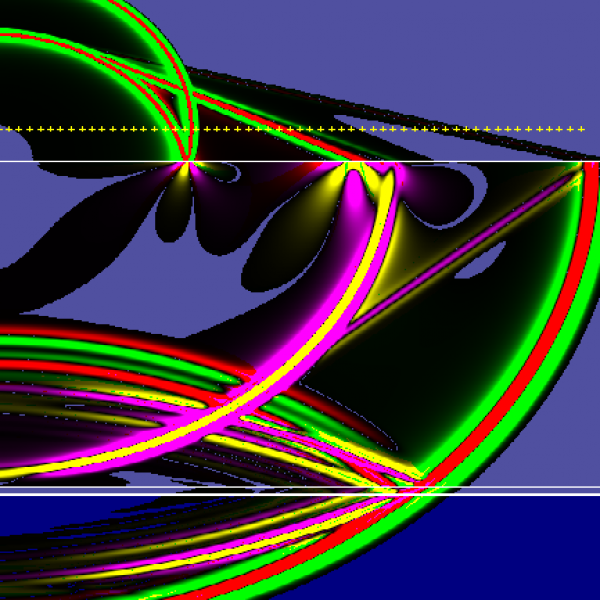

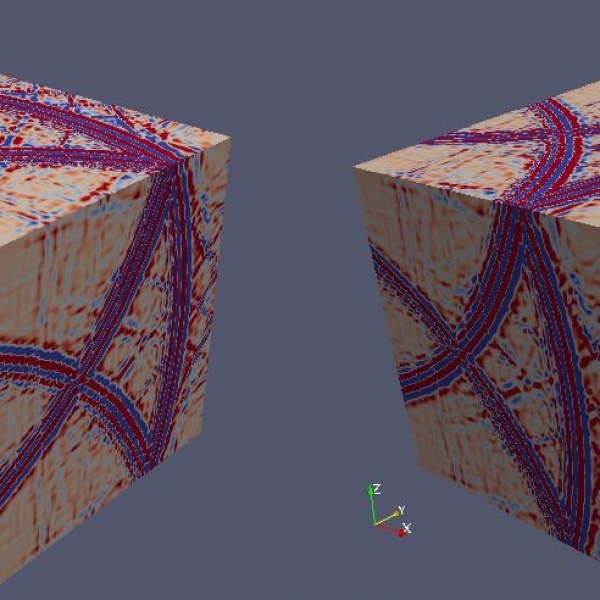

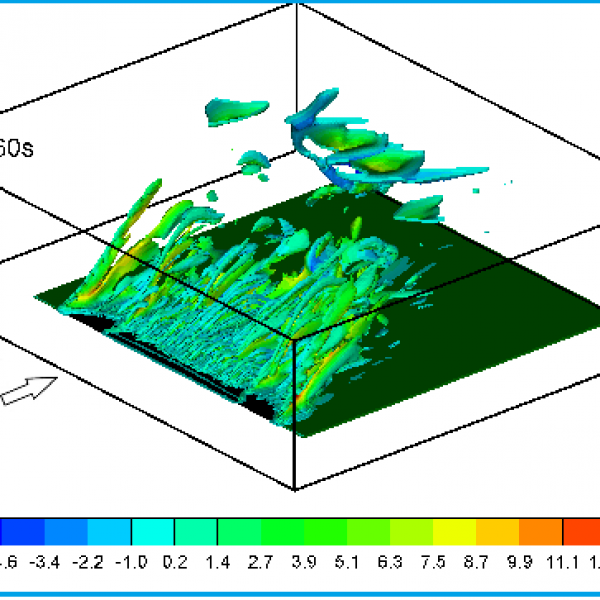

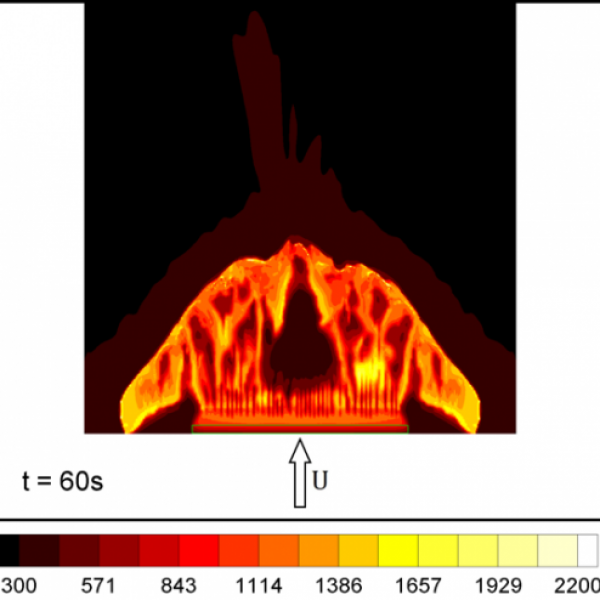

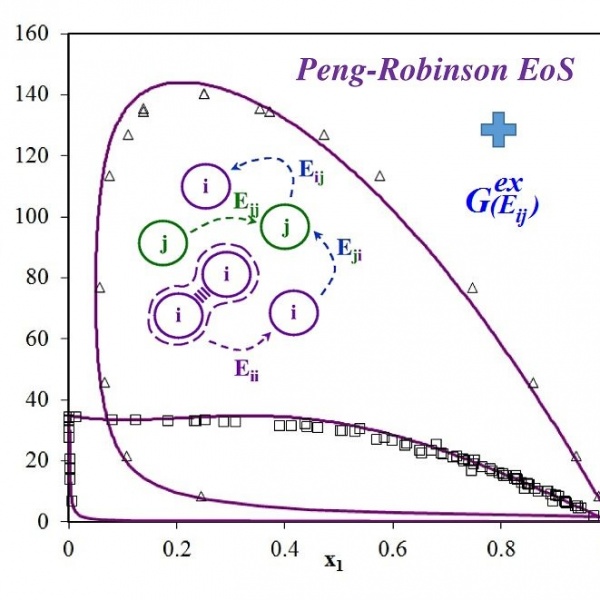

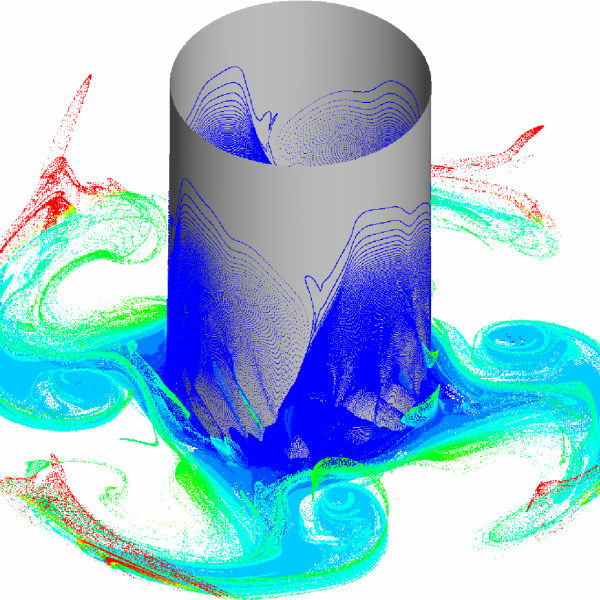

This thesis investigates the stability of premixed hydrogen–air flames in a Hele-Shaw burner using the Lattice-Boltzmann method. Hydrodynamic and thermodiffusive instabilities are analyzed in both two- and three-dimensional configurations, with and without heat losses at the walls. The simulations reveal the conditions for symmetry breaking and quantify the influence of the Lewis number, channel width, and wall heat losses on flame morphology and propagation speed. Reduced-order models are developed to predict flame front geometry, cusp formation, and flame speed evolution.

These results improve the understanding of confined hydrogen flames and provide predictive tools for the design of safe and efficient micro-combustion systems.

Keywords: Flame instabilities, Laminar flame, Confined flow, Hele-Shaw burner

Jury

Carmen JIMENEZ ; CIEMAT, Madrid ; Rapporteure

Laurent SELLE ; CNRS IMFT, Toulouse ; Rapporteur

Andrea GRUBER ; SINTEF, Trondheim ; Examinateur

Heinz PITSCH ; RWTH Aachen University, Aachen ; Examinateur

Luc VERVISCH ; INSA Rouen Normandie, Saint-Etienne-du-Rouvray ; Président de jury

Pierre BOIVIN ; CNRS M2P2 ; Directeur de thèse

Christophe ALMARCHA ; Aix-Marseille Université ; Co-Directeur de thèse

Bruno DENET ; Aix-Marseille Université ; Co-Encadrant de thèse